Granito 73010

for 20 SQM (Can mix and match)

*This product is made to order, lead time is approximately 8-12 weeks.

Description

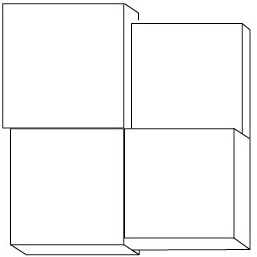

The Granito Classic is an exceptionally durable, traditional tile that combines lasting beauty with customizable colors and patterns. Made from a blend of colored cement and fine marble or glass aggregates, each tile is polished in our factory to enhance its durability and reveal the stunning decorative details. Granito can be re-polished both after installation and even years later, ensuring its timeless appeal.

Product Specifications

Tile material: Portland cement, marble powder, inorganic cement pigments, sand and aggregates, cement additives and recycled marble and glass pieces

Background: Granite

Tile size and thickness (MM) :

30x30 CM / 30x60 CM / 60x60 CM — 16 MM

40x80 CM / 80x80 CM / 60x120 CM — 20 MM

Product Details

Surface Type: Glossy/Satin

Finish Type:

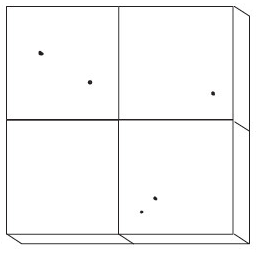

Color Variation: Level 3

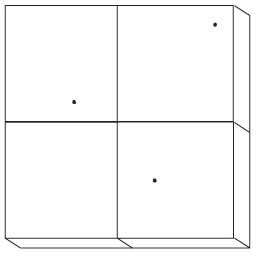

Texture Variation: Level 1

Size Variation: Level 1

Pits / Chips: Level 1

Cracks / Crazing: Level 1

Iron Spots: n/a

Specification Sheet

There are no norms or regulations that are applicable to Granito products. The tests described below were carried out, at the request of our factory, following the norm UNE_EN 13748-1 for Terrazzo for indoor use. The UPEC classification does not cover this type of tiling, nor any of our other cement-based tiling.

Tests carried out in January 2016 by the Getinsa-Payma laboratory (Barcelona) on plain and patternes Granito tiles of size 20x20 cm and thickness 18 mm.

Flexural strength: 8,7 MPa

Standard : >= 4 MPa

Abrasion resistance: 14,0 mm

Standard : <= 25 mm

Surface water absorption: 0,17 gr / cm2

Standard : <= 0,4 gr / cm2

Slip resistance: USRV 46 value

Class 3 >URSV 45

- Interior surfaces with slope greater than 6º

- Wet interior surfaces or industrial surfaces

- Outdoor areas, swimming pools

Notes regarding slip rates:

The more polished and shiny a surface is, the more slippery it becomes. Conversely, a matt surface polished with 60 grit will not be very slippery. The maintenance and application of wax, wether anti-slip or not, are not essentially affecting the slip rate.

VOC Emission tests

Eurofins product testing, 2021

- French VOC regulation (DEVL 1133129ª):A+

- French CMR components (DEVP0908633A and DEVP0910046A) :PASS

- Italian CAM Edilizia (GU n.259):PASS

- ABG/AgBB (Ausschuss zur gesundheitlichen Bewertung von Bauprodukten):PASS

- Belgian Regulation (C-2014/24249):PASS

- Indoor Air Comfort GOLD (Eurofins):PASS

- BREEAM International:Exemplary level

- LEED v4.1 BETA:PASS

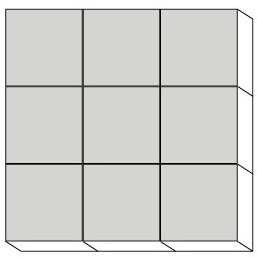

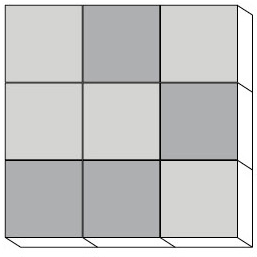

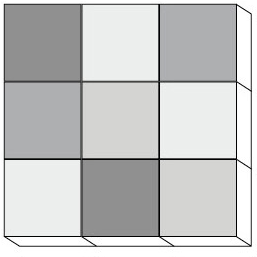

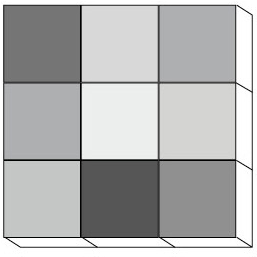

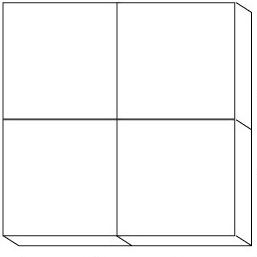

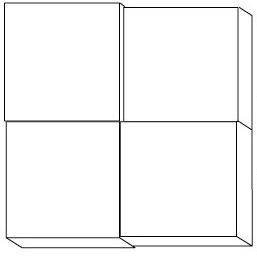

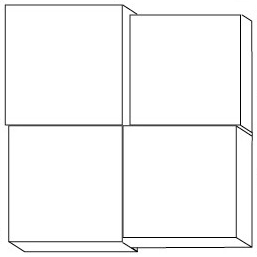

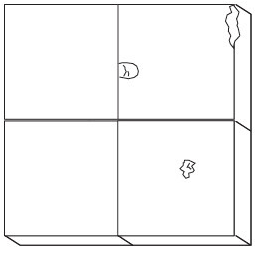

Color Variation: Level 3

Texture Variation: Level 1

Size Variation: Level 1

| CATEGORY | LEVEL 1 | LEVEL 2 | LEVEL 3 | LEVEL 4 | LEVEL 5 |

|---|---|---|---|---|---|

| COLOR VARIATION |

low |

slight |

medium |

heavy |

extreme |

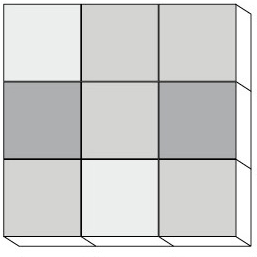

| TEXTURE VARIATION |

smooth |

slight |

medium |

heavy |

N/A |

| SIZE VARIATION |

slight |

medium |

heavy |

extreme |

N/A |

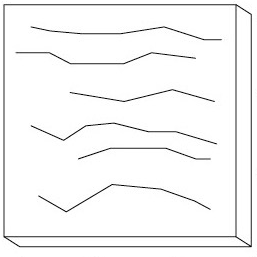

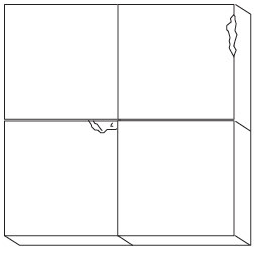

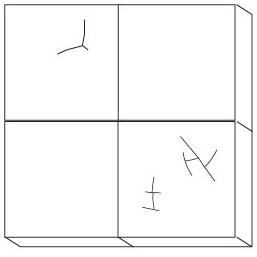

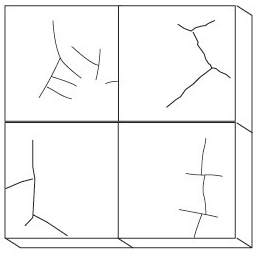

Pits / Chips: Level 1

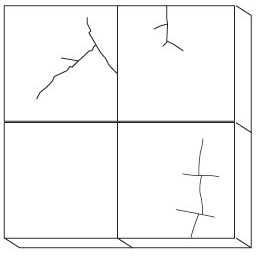

Cracks / Crazing: Level 1

Iron Spots: n/a

| CATEGORY | LEVEL 1 | LEVEL 2 | LEVEL 3 |

|---|---|---|---|

| PITS / CHIPS |

will occur |

slight |

medium |

| CRACK / CRAZING |

will occur |

slight |

medium |

| IRON SPOTS |

will occur |

medium |

heavy |

How its made

Before you order

Sampling

Pozzilo’s products are mostly handcrafted and may vary in size, texture, color, shade, and inherent imperfections, and production batches or "lots" of artisan tiles can vary. Therefore, the images on the website photography or your sample order may not match the current lot or your full tile order.

Order Enough Tile

Pozzilo recommends grout joints for some product collections, which may be automatically calculated in the “pieces per square foot” calculation. It is the sole responsibility of the installer or project manager to measure accurately and ensure that grout joint sizes are factored into product order quantities. Have your installer advise you how much extra tile you should order. For many collections, we recommend a minimum of 20% overage to accommodate routine breakage, etc. However, some collections have a recommended overage of 20% to 30%. Please be sure to check for your specific tile what our recommended overage is. If you wish to achieve a specific design aesthetic, we recommend ordering at least 30% - 35% MORE than the project requirements to “cherry-pick” tiles.

Avoid Add-On Orders

Because of the nature of the materials and the handcrafting process, Pozzilo can never guarantee a color match from previous orders. Avoid add-on orders by having your installer or project manager to measure carefully and order enough overage.

Hire An Experienced Installer

We strongly suggest choosing installers who have shown their commitment to their craft and remained current with the latest methods and materials. We suggest requiring references and a portfolio along with a bid or estimate to ensure the installer has successfully completed work of similar size, scope, and complexity. Your installation will only be as good as your installer. Pozzilo does not offer installation support.

No Returns

Pozzilo does not accept returns on any product orders.

Installer Checklist

Design Professional/Installer Guidelines

Pozzilo offers general information about our tiles and their unique qualities and usages. Pozzilo does not provide project management or installation advice; that is the responsibility of your experienced installer.

Before: Ordering + Planning

- CORRECT TILE QUANTITY/OVERAGE. Request that your design professional/installer measure and determine the precise square footage needed for the project. (We recommend adding a minimum of 20% more to account for overage, although certain materials and collections suggest 20-30% for overage.)

- TIMING. Budget enough time for the installation with your design professional/installer for the type of tile you are thinking of installing and make sure to take into account shipping delays.

- SAMPLING. Ensure that your design professional/installer provides samples using the product you are interested in. (Please note that most of our tiles are handcrafted using natural materials, and product samples or website photography may not match the full tile order.)

- TECHNICAL SPECIFICATIONS. You and your design professional/installer must be familiar with all material specifications (on each product page). If you do not understand them, please email hello@pozzilotile.com

- GROUT. You and your design professional/installer are responsible for selecting a grout that meets your project’s specific needs. Refer to the ANSI and/or ISO standards for your project. Please note that Pozzilo does not provide specific grout brand, type, or color recommendations.

Overage/Wastage

Industry standard suggests adding at least 20% overage due to tile cuts, potential shipping breakage, or future repairs. This will allow your contractor to cherry-pick the tiles most desirable for your project.

Delivery

When the tiles are delivered, be on-site with your design professional/installer to inspect them together.

Preparation For Installation

- REQUIRE YOUR INSTALLER PERFORM A “DRY RUN”. Before installing, make sure to lay out and blend ALL BOXES of your tiles so that your variations in color, and tiles that bear chips and pits are artfully placed as you would like. The best placement of these nuances throughout your installation must be guided by you and/or your design professional to realize the best possible blend of your shipment of our limited-availability tiles. Your installation is only as good as your DRY RUN.

- REQUIRE MOCK-UP BOARDS. We urge all our clients to require creation of mock-up boards before installation. This allows you and your designer/installer to test your tile layout in mock-up form and lets you view your design in the space and lighting in which it your tiles will be installed. Mock-ups also help ensure your grout color and grout joint size are to your liking.

- SUBSTRATE. Before installation, make sure your project engineer and installer have prepared your substrate properly. Surfaces should be flat, clean, and free of any sealants, waxes or other contaminants prior to installation. Also, ensure that any drainage requirements have been taken into consideration before beginning installation.

- EXPANSION JOINTS. Confer with your installer and project engineer that expansion joints are placed at recommended intervals (these will vary depending upon your project’s needs) and are properly constructed.

At Installation

- PROCESS. Ensure that your design professional/installation team:

- Prepares tile for installation (including pre-sealing if required)

- Select the proper thinset and grout for your project, and prepare and apply the thinset mortar and grout according to the manufacturer’s instructions.

- Properly cleans and seals the tiles and grout lines as a final step, if required.

- Makes recommendations for ongoing care (keeping in mind material guidelines for the specific tile and material installed)

Grout + Sealant

Pozzilo recommends using mortar and grout that comply with the ISO 13007 classifications suitable for your project. Please consult with your installation professional to make these determinations.

Installation

Place on a levelled concrete slab using standard cement adhesive. Double bonding (apply on floor and back of the tile) to properly set the tiles.

Thin grout lines (1 to 2 mm) filled with liquid cement based grout. Leave a thicker gap for under-floor heating and outdoor installations (min 2mm).

With unicolour tiles, coloured grout in the same tone as the tiles may be used if an abrasive polishing is carried out at the end of the installation.

GroutingDomestic floors - Sealing is necessaryHeavy traffic floors: Crystallise and strengthen GranitoCrystalliser for household useCleaning and daily maintenance

Related Products

- Pozzilo TileTerrazzo Geometric Rectangle 01RM 35,000

- Pozzilo TileTerracotta 10, 10x10 CMRM 7,200

- Pozzilo TileTerracotta 07, 20x23 CMRM 5,900

- Pozzilo TileTerracotta 10, 21x7 CMRM 6,800

Be the first!

Sign up for perks, including first dibs on our newest collections.

Company

Help

Family of Brands

© 2025 Pozzilo Tile, All rights reserved. Powered by Shopify

Select optionsPOPULAR SEARCHESAbout UsContact UsFAQTrade Program

Grouting

The pigments contained in coloured grout may infiltrate the pores of the tiles and stain them irreversibly.

After humidifying the tiles, the grout space should be filled with very liquid NON-PIGMENTED cement grout filler using a filing knife. Excess grout should be removed immediately with a damp sponge. Avoid spreading the grout onto the whole tile surface.

Domestic floors - Sealing is necessary

A sealer is an impregnating liquid that fills the pores in the surface of the tile. It is usually applied once after laying and on a clean and dry floor. The sealer limits the absorption of liquids and grease, helping protect the tiles against stains. Apply lightly with a brush or a wool roller, as the tiles saturate quickly. Once absorbed, remove any excess of sealer and even out the distribution with a cloth. Excess sealer left on the surface will dry and leave shiny or yellowy residues that can only be removed with a soft abrasion.

Heavy traffic floors: Crystallise and strengthen Granito

Crystallisation is a mechanical/chemical process that attaches fluorosilicates (of sodium or magnesium) to the crystals in the surface of limestone type floors, hardening and waterproofing surfaces. Marble, travertine, sedimentary stones, Terrazzo and Granito can all be crystallised, after the installation or at any time during the life of the floor, to restore and regain the original look.

A professional natural stone and marble care expert should carry out the crystallisation using a single disc machine, a stainless steel or bronze wool disc and fluorosilicate based products.

Crystalliser for household use

For domestic use, Mosaic offers a more practical and non-toxic crystalliser (without fluorosilicates). This product is best applied using a buffing machine with a steel or fibre disc. Contact a representative for further information.

Cleaning and daily maintenance

Mop with water and PH neutral soap. Natural PH neutral soap cleans and nourishes the Granito while protecting it. Do not use harsh cleaners or acidic and alkaline products that attack limestone based floors. Colourless wax for marble can be used as part of maintenance from time to time. It will help enhance colours, create a patina and protect the floor.